The Ruston and Hornsby 3XHR Single Cylinder Diesel Engine

17 bhp

Governed speed 370 rpm

7¼" bore x 13½" stroke

Serial number 297647

This engine was installed in the engines laboratory of the college where I used to work and was disposed of in 1987.

You can hear a recording of it in action below. When it was run for students, it took three people to start it, two to crank it over and the third to drop the inlet valve lifter when it had been cranked up to a suitable speed. But you could just about manage it single-handed as I did here although at the first attempt, the engine didn't fire.

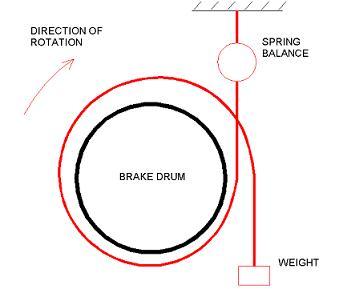

The output power of the engine was measured by a brake. This is a means of applying a load to an engine and in this case it was a heavy rope that wrapped round the brake drum that was fixed at the top end (see below for diagram of the arrangement). The load on the engine was increased by adding weights to the free end. As a result of the brake rubbing on the drum much heat was generated and so the drum was filled with cooling water from a tap to stop the rope catching fire. The water stayed in the drum because of centifugal force and only all fell out, very hot, at the end of the run when the engine came to a stop.

You can hear a recording of it in action below. When it was run for students, it took three people to start it, two to crank it over and the third to drop the inlet valve lifter when it had been cranked up to a suitable speed. But you could just about manage it single-handed as I did here although at the first attempt, the engine didn't fire.

The output power of the engine was measured by a brake. This is a means of applying a load to an engine and in this case it was a heavy rope that wrapped round the brake drum that was fixed at the top end (see below for diagram of the arrangement). The load on the engine was increased by adding weights to the free end. As a result of the brake rubbing on the drum much heat was generated and so the drum was filled with cooling water from a tap to stop the rope catching fire. The water stayed in the drum because of centifugal force and only all fell out, very hot, at the end of the run when the engine came to a stop.